Useful Links:

1) Open or create a project

You can open a project to start processing or create a new project. If you create a new project, you need to design patterns and set parameters from scratch.

- Open a project

In the upper left corner of XCS, click the  icon and select Open project… In the pop-up window, select a file of type xTool Creative Space Project (. xcs) and click Open.

icon and select Open project… In the pop-up window, select a file of type xTool Creative Space Project (. xcs) and click Open.

Note: The project file can contain information such as processing patterns, processing modes, and processing parameters. However, if the machine model, processing mode, or material thickness used in the project varies from the current situation, you need to reset the corresponding parameters.

- Create a new project

When you open XCS, a new blank project will be created by default. You can click the  icon and select Save in the upper left corner of XCS to name and save the project.

icon and select Save in the upper left corner of XCS to name and save the project.

2) Select the XTool-S1 laser in the Device Selection Menu

On the main dashboard or project page, look for the Device Selection or Add Device section. This is typically located in the top right toolbar or within the settings menu. Look for the XTool S1 if using the smaller diode laser.

3) Select the processing mode and material name

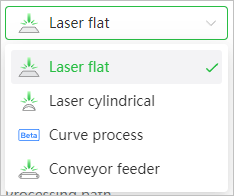

(1) On the right side of the XCS home screen, select Laser flat.

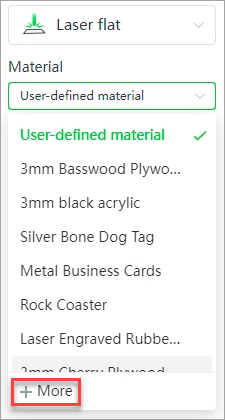

(2) In the drop-down list of Material, select the name of your material.

Note 1:

If you can’t find your material in the list, you can click + More to search among more materials in the xTool SELECTED online material center.

If you still can’t find the name of your material, you can select User-defined material.

Note 2:

After you select a material on the material list or xTool Selected online material center, the software will automatically focus and set other parameters for laser processing.

The default settings apply to xTool materials. You can adjust the settings based on your needs.

(Optional) (3) Turn on or off Laser module position based on your need.

Note: If you turn on Laser module position, XCS will display the position of the laser module in real time. The red cross in the canvas indicates the laser module, and the coordinates of the laser module are shown in the Laser module position section.

4) Set the laser focus

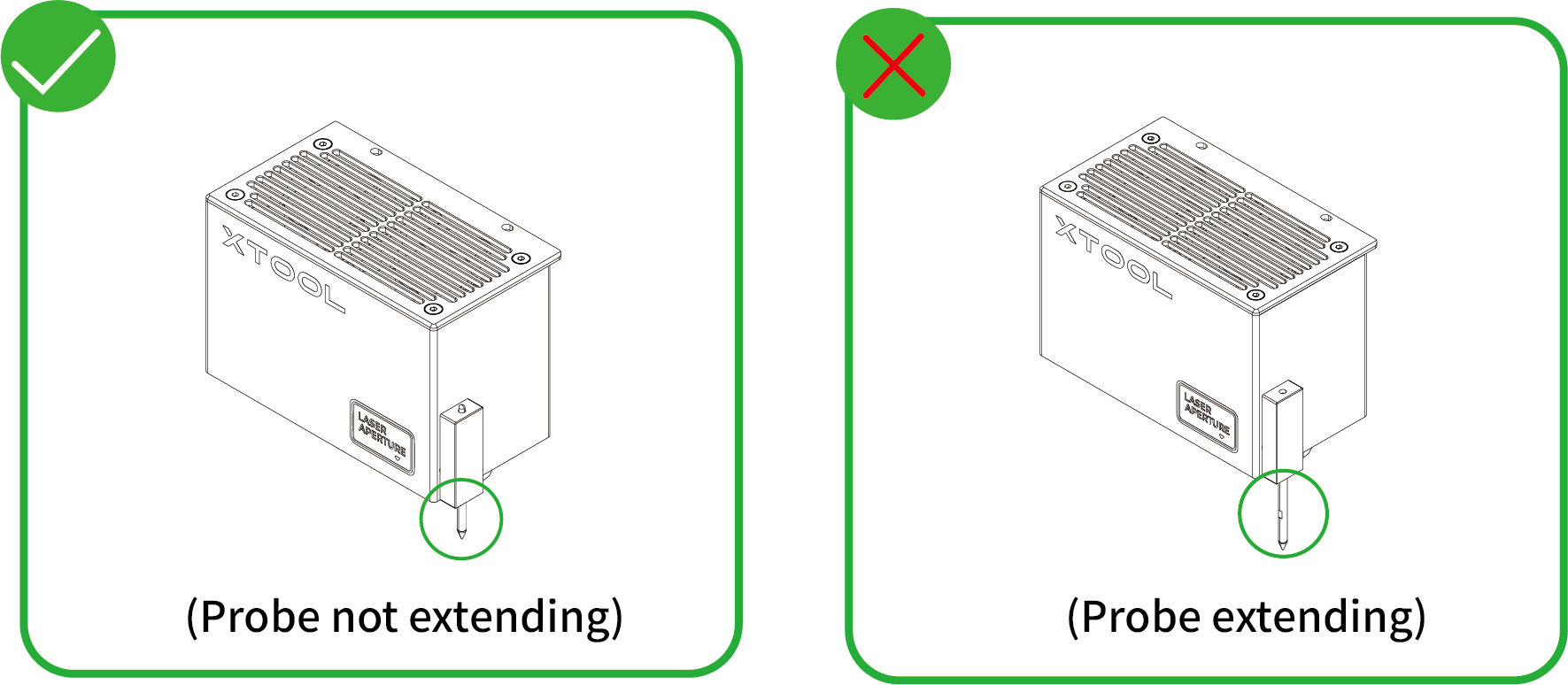

xTool S1 has a distance sensor, which can measure the distance between the laser module and the material surface. You can also manually measure and calculate the distance between the laser module and the material surface, and input the obtained values into XCS. Before processing, xTool S1 will perform auto-focus based on the Distance parameter.

- Auto measure

(1) Move the laser module over the material. Ensure that the locating spot falls on the surface of the material.

(2) On the right side of XCS, click the  icon under the Distance parameter, and xTool S1 will automatically measure the distance from the laser module to the material surface.

icon under the Distance parameter, and xTool S1 will automatically measure the distance from the laser module to the material surface.

Note: Before auto-measure, ensure that the probe of the distance sensor is not extending.

- Manual measure

(1) Use a ruler to measure the distance from the surface of the material to the top of the laser module.

(2) Subtract 100 mm (3.937 inches) from the measured value from step (1), and input the calculated value into the Distance parameter on the right of XCS.

5) Mark the target processing area on the canvas

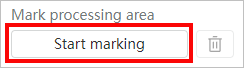

(1) On the right side of XCS, click Start Marking.

(2) Select a marking mode based on the shape of the target processing area, and click Start marking.

(3) Manually move the laser module to make the red cross spot fall at a vertex of the target processing area, and press the button on the device to record the position. Then, repeat the same steps to record the other required vertex(es) for the target processing area.

(Here the Rectangle mode is used as an example.)

(4) Click End marking > Done, and then the target processing area will be marked out on the canvas.

(Optional) (5) After the processing area is marked, you can turn on Auto-snapping to help you position elements. When you move an element close to the center of the marked area, the element will be pulled to the center.

To turn on Auto-snapping, click the  button on the top-left corner of XCS and toggle on Auto-snapping in General.

button on the top-left corner of XCS and toggle on Auto-snapping in General.

6) Design objects for processing

Note: The target processing area is marked out by a green perimeter as a rectangle. You can design objects within this area.

(1) Use the tools to the left side of the canvas to create objects. You can import images, insert shapes, enter text, or draw vector graphics.

Note: XCS supports importing the following image formats: SVG, DXF, JPG, JPEG, PNG, BMP, etc.

(2) Select the objects and use the toolbar above the canvas to further edit the objects.

Note: If you select an image object, you can edit the image by using the tools on the right side of the canvas.

7) Set parameters for processing

Select objects on the canvas. Then, on the right side of the XCS home screen, set parameters for the selected objects.

Note:

You need to set parameters for every object. A missed object may fail to be processed.

The parameters that can be set for bitmap objects and vector objects are different. You can select multiple objects of the same type and set parameters for them at once.

- For bitmaps

- For vectors

8) Preview the processing area

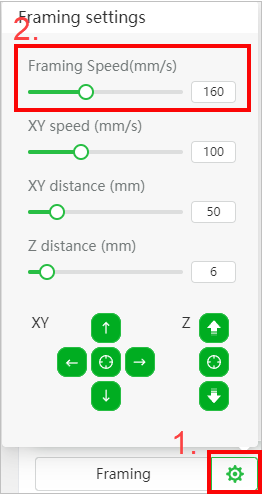

(1) At the bottom right corner of the software, click the .png) icon next to the framing button to set the framing speed.

icon next to the framing button to set the framing speed.

Note: You can tap the arrow buttons to control the movement of the laser module. The other three parameters allow you to configure how the laser module moves with every tap on an arrow button.

XY speed (mm/s): The moving speed of the laser module in X and Y directions.

XY distance (mm): The moving distance of the laser module with each tap on an XY arrow button.

Z distance (mm): The moving distance of the laser module with each tap on a Z arrow button.

(2) Close the lid of xTool S1, and then click Framing in the software. Press the button on xTool S1 to start framing. The laser spot will move along the boundary of the processing pattern on the material so that you can preview the processing area.

(3) After you confirm that the processing area is proper, click Framing completed in XCS. If the area is not ideal, you can adjust the material position or adjust the element positions in the software, and then preview the processing area again.

9) Start processing

Turn on the switch for the exhaust fan!!

Note: If you use the infrared laser module at a temperature of 10 ℃ or below, please preheat the laser module for 2 minutes to ensure better processing results.

(1) On the bottom right corner of the software, click Processing.

(2) Preview the processing objects in the software. Then, in the upper right corner of the software, click Start.

(3) Close the lid of xTool S1. Then, press the button on xTool S1 to start processing.